![]() Download PDF528.56 KBBattery Electric Vehicles or BEVs. Clean. Quite. Efficient. The quintessential poster-child for "clean energy." After all, running a BEV car produces ZERO emissions. What could be cleaner than that? Turns out, when we do the math - plenty.

Download PDF528.56 KBBattery Electric Vehicles or BEVs. Clean. Quite. Efficient. The quintessential poster-child for "clean energy." After all, running a BEV car produces ZERO emissions. What could be cleaner than that? Turns out, when we do the math - plenty.

Proponents of 100% BEV as a complete solution to our ever-rising pollution and GHG emission levels leave quite a bit out of their public calculations. No one can argue that tail-pipe emissions are zero. BEVs do not even have a tailpipe. But that does not mean they are as clean and green as we are meant to think. Pamela Coke-Hamilton, UNCTAD’s director of international trade states that consumers are unaware of the real cost. “The dirty aspects of the production process are out of sight.”

First, electric car batteries don't come cheap - both in consumer costs and human/environmental costs. According to TheDrive.com, Tesla model 3 replacement runs nearly $16,000. Second, there's a hidden cost to pay for these large and heavy batteries (about a 1,000 pounds on the Tesla model 3). These large-scale human and environmental cost comes from the extraction and refinement process, as well as the ultra-heavy footprint for over-seas shipping. Displaced indigenous tribes and ever-growing environmental degradation are just the beginning of the hidden carbon-footprint BEVs make.

Lithium-ion batteries are the most common type of batteries used in electric vehicles. As the name implies, lithium is required for the manufacturing of these rechargeable batteries. But much more goes into these batteries than just lithium. And "just" lithium" requires enormous natural resources in order to extract this mineral.

Lithium-ion batteries are the most common type of batteries used in electric vehicles. As the name implies, lithium is required for the manufacturing of these rechargeable batteries. But much more goes into these batteries than just lithium. And "just" lithium" requires enormous natural resources in order to extract this mineral.

In a 2022 article, The BBC points out several troubling trends in the industry. First, only about 5% of lithium ion batteries are recycled, because it costs more to recycle than to just build a new one. And the costs associated with building new batteries are staggering. To produce one ton of lithium requires 2.2 million liters of water (500,000 gallons). Statista lists In 2018, world-wide lithium mining produced 95,000 tons of lithium. The water-cost for this totals 47.5 billion gallons of water, the equivalent of 72,000 Olympic-sized swimming pools.

That's just for one year. So much water is being used to mine these "clean energy solutions," that, combined with the human and environmental degradation cost, plus shipping these ores across several oceans to different processing sites, the end result seems to be exacerbating the effects of climate change and not mitigating it. According to the BBC, these mining operations lead to "declining vegetation, hotter daytime temperatures and increasing drought conditions" -- the very thing that "going BEV-green" is supposed to prevent!

Most of these toxic batteries simply end up in the landfill, where they can explode if they are not correctly dissembled. The only option to date, to disassemble these complex batteries, is to do it by hand, which is  expensive and takes a lot of time. Considering the lower cost to build a new one, most are simply dumped and forgotten. These batteries can explode, and when they do, as the Hill reports, firefighters need to use 40 times the amount of water to put out a fire. To extinguish a Tesla car fire, firefighters report using between 30,000 and 40,000 gallons of water, compared to about a 1,000 gallons of water to extinguish a piston engine car-fire.

expensive and takes a lot of time. Considering the lower cost to build a new one, most are simply dumped and forgotten. These batteries can explode, and when they do, as the Hill reports, firefighters need to use 40 times the amount of water to put out a fire. To extinguish a Tesla car fire, firefighters report using between 30,000 and 40,000 gallons of water, compared to about a 1,000 gallons of water to extinguish a piston engine car-fire.

Lithium is not the only hidden cost associated with producing these lithium ion batteries. Depending on the cathode type used, the battery may require a chemical bath of Lithium Cobalt Oxide (LCO, Lithium Manganese Oxide (LMO, Lithium Iron Phosphate (LEP, Lithium Nickle Manganese Cobalt (NMC, or Lithium Nickle Cobalt Aluminum Oxide or (NCA). The four main elements needed for manufacturing the anodes of these batteries are cobalt, lithium, manganese, and natural graphite. Add in the chemical bath called electrolytes and separators, we get half a ton of rare minerals and toxic chemicals that propel our BEVs down the road.

All too often, the mineral mines are located in developing countries with poor environmental oversight. Over half the world's lithium resources are found in some of the driest regions on the planet. These lithium mines dot the salt flats in Andean regions of Argentina, Chilie, and Bolvia, pitting native-peoples against the voracious needs of the industrialized world for water to extract these minerals from the earth. Lithium isn't the only mineral extracted under often brutal conditions.

Most of the cobalt resources are found in the Democratic Republic of the Congo (DRC) and Zambia. As the Guardian reported in 2019, the exploitation of children killed in these cobalt mines resulted in a landmark lawsuit against the tech giants Dell, Apple, Google, Microsoft and Tesla. The lawsuit alleges that these tech giants have profited from the labor of children. Considering the DRC is one of the poorest and most unstable countries in the world, the Guardian points out that it is no surprise that "the extraction of cobalt from DRC has been linked to human rights abuses, corruption, environmental destruction and child labor."

Critics might point out that the cost of any modern manufacturing has these 'hidden" costs, and that this is just the "cost of doing business." They point out that the zero emissions are exactly what is needed to wrangle the climate crises we find ourselves embroiled in. Who can argue with "zero emissions." But even here, in measuring CO2 and GHG emissions against a gasoline engine, we find disturbing and unpleasant facts that the industry does not want to talk about.

Can a BEV actually produce more emissions than a piston-engine?

The short answer is yes, if we change our perspective from the tailpipe, to the electrons actually charging the batteries. To get a factual view of this we have to look at the different energy and fuel feed stocks being converted to power and transmitted over the national grid in the US as opposed to the power generation.

The short answer is yes, if we change our perspective from the tailpipe, to the electrons actually charging the batteries. To get a factual view of this we have to look at the different energy and fuel feed stocks being converted to power and transmitted over the national grid in the US as opposed to the power generation.

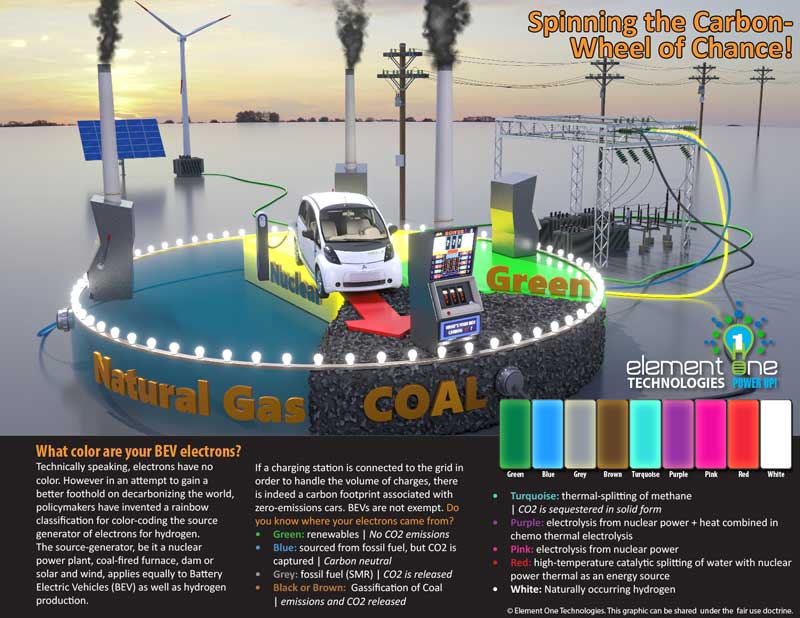

Even if we do not factor in the very real humanitarian and environmental and operational costs of producing batteries for BEVs, or the enormous carbon footprint involved in transporting these ores half way around the world inside the most polluting transports ever devised - cargo ships - we still need to factor in the color of electrons charging BEVs all across the world. (Hint. It's not all solar and wind). Sixty percent of the grid power electrons are fossil based. Wind and Solar only make a mere pittance of 12% of the power consumption across the US. Therefore - trying to find renewable electrons int he grid to charge a BEV is like trying to find a needle in 3000 square miles of Yellowstone park. The EXACT same electrons that are transmitted over the grid to charge a BEV are exactly the same electrons used to produce hydrogen. If hydrogen is called "grey" due to the use of natural gas to produce that hydrogen - that natural gas is burning in power plants to charge a Tesla!

Let's Google Tesla charging station, and select images. You will find hundreds of images of solar-panel bejeweled charging ports that, at first glance, suggest that these stations are charging the BEVs using 100% green and clean solar power. Yet, when we do  the math and breakdown the reality of these charging stations, we quickly realize that many if not the majority of these charging ports are using grid energy. Which means we need to color-code the electrons for BEVs, just like others have done for hydrogen production.

the math and breakdown the reality of these charging stations, we quickly realize that many if not the majority of these charging ports are using grid energy. Which means we need to color-code the electrons for BEVs, just like others have done for hydrogen production.

This new Tesla V3 Supercharging station that just came on line "which supports a peak rate of up to 250 kilowatts,". and has 39 charging stations. It has 576 solar panels. Ill assume the newest 400 watt solar panels. With two roof panels systems that totals 230 kWs of power output. Further - these solar panels can only operate 5.25 hours per day average over the year due to the capacity factor. The maximum power this new V3 Supercharger can output is 1,209.6 kWhs average per day. The new Tesla Model 3 has a 82 and 100 kWh battery. So if we divide these cars batteries 50/50 between 82 kWhs and 100 kWhs - we need 3640 kWhs to service 39 Tesla cars. Assuming also that the V3 Supercharging stations also have some assisted battery backup to decrease charging times BUT that will never make up for the difference between the solar output and the kWhs required to charge the batteries. Therefore - it must be supplemented with not green grid power. If there were 39 Teslas that rolled into this station to charge at the same time - it will have to rely on grid power to charge most of the cars. The solar array would not be able to handle the load fast (slow) charging times drivers demand. Unless - you only want a 15 minute charge to get to your next destination or another charging station.

And once we do that, the math very quickly points out something rather unusual. All things considered - charging a Tesla 3 from the gird can produce a larger CO2 footprint than a regular  gas-powered piston car. The majority of the US grid - and in most countries around the world are still powered by fossil based resources. Be it Coal or natural gas. According to the EIA this projected energy consumption chart clearly reflects the resources that are and will be powering up the U.S. grid.

gas-powered piston car. The majority of the US grid - and in most countries around the world are still powered by fossil based resources. Be it Coal or natural gas. According to the EIA this projected energy consumption chart clearly reflects the resources that are and will be powering up the U.S. grid.

Petroleum: in the 10% group - Natural Gas: 34% - Coal 10% - Nuclear: 12% - Renewable Energy: 44% (10.2 quadrillion BTU). Renewable Energy is broken down as: Hydroelectric: 12% - Biomass: 43% (biomass is broken down as follows: Wood: 20% - Biofuels: 20% and Biomass Waste: 4%) Wind: 24% - Solar: 9% and Geothermal: 2%.

Though hydroelectric power joined the list of Renewable Energy late in the development of REs - some states still don't classify hydroelectric as renewable due to the devastation that come along with building a hydroelectric dam. The last hydroelectric dam built in in the U.S was in 1979. So in the push for RE - hydroelectric sits at the bottom of the pile of NEW Renewable projects.

Each step of the process incurs hits on efficiency and CO2 output i.e. one ton of coal creates 5,720 pounds of CO2 emissions when it is burned. The electricity generated per ton of coal is only 0.4 x 6,150 kWh or 2,460 kWh/ton. The Tesla Model 3 has the optional 100 kWh battery. Since the grid is AC based - the AC-DC converter onboard all Tesla has an automatic conversion loss of 12%-14%. That means that the charging capacity jumps to 112 kWhs to 114 kWhs. Using the grid to charge a Tesla Model 3 using that "1 ton of coal" configuration equates to 24.6 charges to 100%. That 0-100% charging process that requires 100 kWhs (112 kWhs to 114 kWhs factual) produces 169.5 pounds of CO2 to drive 350 miles. Burning gasoline in an car that averages 25 mpg produces 19.37 pounds of CO2 per gallon. This car would consume 14.58 gallons of fuel driving 350 miles - producing 282.5 pounds of CO2. But due to the 40% efficiency of a coal fired power plant or of natural gas - 169.5 pounds of CO2 now becomes more than double - lest we forget the additional 14%-16% AC-DC conversion. So one asks, "where's the proof of more CO2 emitted charging a Tesla Model 3?" It's in the math....

Due to the 33% efficiency of coal fired power plant - a 42% efficiency of a natural gas powered plant and the line losses of 8% electron transmission BEFORE one electron is activated for charging a Tesla Model 3 - the power plant has burned more than twice the tonnage  of coal that emits the CO2 equivalency that increases the direct emissions at the plant. Therefore - 169.5 pounds of CO2 emitted in direct proportion to charge the Tesla 100 kWh battery now becomes more than double the amount of direct emissions of CO2 for the same amount of time charged for the 100 kWhs. Now we go from 169.5 pounds of CO2 emitted to close to 350 pounds of CO2. Far more emissions than a conventional ICE vehicle traveling the same exact distance.

of coal that emits the CO2 equivalency that increases the direct emissions at the plant. Therefore - 169.5 pounds of CO2 emitted in direct proportion to charge the Tesla 100 kWh battery now becomes more than double the amount of direct emissions of CO2 for the same amount of time charged for the 100 kWhs. Now we go from 169.5 pounds of CO2 emitted to close to 350 pounds of CO2. Far more emissions than a conventional ICE vehicle traveling the same exact distance.

If we peer into the energy resources of California by type -we see the largest percentage of energy produced is by far natural gas. The rule language simply states that the output will be calculated as the electric output plus the thermal output in MW based on the conversion of 1 MWh equals 3.413 MMBtu of heat output - 1 MMBTU equals 1,000.00 cu ft of Natural Gas. To express the efficiency of a generator or power plant as a percentage, divide the equivalent Btu content of a kWh of electricity (3,413 Btu) by the heat rate. For example, if the heat rate is 10,500 Btu, the efficiency is 32.5%. If the heat rate is 7,500 Btu, the efficiency is 45.5%. According to the EIA, "About 117 pounds of CO2 are produced per million British thermal units (MMBtu) equivalent of natural gas compared with more than 200 pounds of CO2 per MMBtu of coal and more than 160 pounds per MMBtu of distillate fuel oil."

Considering 100% natural gas grid connect for charging - there are 3,413 BTUs per kWh in natural gas power generation. A Tesla Model 3 battery is rated at 100 kWhs - plus the 14% - 16% - energy losses on the Ac to DC conversion to charge the battery - we must calculate on the low end 114 kWhs needed to charge the battery. One kWh of natural gas produces (3,413 BTUs) emitted an average of 549 grams (19 ounces) CO2 per kilowatt hour. Multiply CO2 rate by 114 kWhs to charge the Tesla model 3 - that charging produces 62,586 grams - 137.97 lbs of CO2 per charge (350 miles or 5,3217 lbs per year @ 13,500 miles average) compared to 282.5 lbs of CO2 emissions generated from a conventional gasoline car driving 350 miles. But keep in mind - the above is just the CO2 emissions produced using natural gas to produce electricity to charge a Tesla but this equation does not account for all the fugitive methane GHGs escaping into the atmosphere BEFORE one kWh is even produced at the power plant. Not to mention the tons of CO2 and GHGs being emitted to mine the coal or develop the gas wells before any chemical to energy conversion is put into play.

If we take this a step further - the claims of anti-hydrogen opponents, "Using hydrogen creates far more emissions and is far less efficient than a BEV" fall flat. With all things considered - if you look at the actual carbon footprint of charging a Tesla Model 3 increases dramatically using the grid - a HFCV far outshines a Tesla in all its supposed energy losses from wells to wheels using direct connect Element One Technologies method of producing, compressing, transporting and distributing hydrogen that has a much smaller carbon footprint than charging a BEV. Therefore – the actual vehicle itself maybe considered a Zero Emissions Vehicle (not considering the CO2 and GHGs emitted during the manufacturing of the battery and the car) but the power to propel that supposed ZEV even one foot is anything but Zero!

https://unctad.org/system/files/official-document/ditccom2019d5_en.pdf

Coal-fired power plant and the electrification of the car industry

According to the data of the EIA, "The amount of heat emitted during coal combustion depends largely on the amounts of carbon, hydrogen, and oxygen present in the coal and, to a lesser extent, on the sulfur content. Hence, the ratio of carbon to heat content depends on these heat-producing components of coal, and these components vary by coal rank.

Carbon, by far the major component of coal, is the principal source of heat, generating about 14,500 British thermal units (Btu) per pound. The typical carbon content for coal (dry basis) ranges from more than 60 percent for lignite to more than 80 percent for anthracite. Although hydrogen generates about 62,000 Btu per pound, it accounts for only 5 percent or less of coal and not all of this is available for heat because part of the hydrogen combines with oxygen to form water vapor. The higher the oxygen content of coal, the lower its heating value. This inverse relationship occurs because oxygen in the coal is bound to the carbon and has, therefore, already partially oxidized the carbon, decreasing its ability to generate heat. The amount of heat contributed by the combustion of sulfur in coal is relatively small, because the heating value of sulfur is only about 4,000 Btu per pound, and the sulfur content of coal generally averages 1 to 2 percent by weight. Consequently, variations in the ratios of carbon to heat content of coal are due primarily to variations in the hydrogen content.

The carbon dioxide emission factors in this article are expressed in terms of the energy content of coal as pounds of carbon dioxide per million Btu. Carbon dioxide (CO2) forms during coal combustion when one atom of carbon (C) unites with two atoms of oxygen (O) from the air. Because the atomic weight of carbon is 12 and that of oxygen is 16, the atomic weight of carbon dioxide is 44. Based on that ratio, and assuming complete combustion, 1 pound of carbon combines with 2.667 pounds of oxygen to produce 3.667 pounds of carbon dioxide. For example, coal with a carbon content of 78 percent and a heating value of 14,000 Btu per pound emits about 204.3 pounds of carbon dioxide per million Btu when completely burned. Complete combustion of 1 short ton (2,000 pounds) of this coal will generate about 5,720 pounds (2.86 short tons) of carbon dioxide."

According to Electrical Power Energy, "In modern society, we cannot think to live without electrical power." In early days electricity was transmitted by using direct current. After Nicola Tesla invented alternating current 1886, this electrical transmission got much popular. Today we can send power through the continent by using this alternating current. Once the length of the transmission line becomes longer, the conductor resistance also gets the increase, so the energy loss also increases. This problem of the AC transmission is solved by using transformers to step up voltages.

According to Electrical Power Energy, "In modern society, we cannot think to live without electrical power." In early days electricity was transmitted by using direct current. After Nicola Tesla invented alternating current 1886, this electrical transmission got much popular. Today we can send power through the continent by using this alternating current. Once the length of the transmission line becomes longer, the conductor resistance also gets the increase, so the energy loss also increases. This problem of the AC transmission is solved by using transformers to step up voltages.

But there is another problem that occurs due to the impedance of the transmission line: another external property called reactance also happens in the transmission lines, and this leads to loss in current for the same voltage. This happens mainly due to the property of inductance and the capacitance of the transmission line. Inductors have commonly resisted the changing in current, and temporarily store energy in the magnetic field. The capacitor is also opposed to the voltage differences and temporarily store energy in the electric field. Altogether this can cause the phase shift between the voltage and the current in the line and also it results from an increase in the resistive losses. Usually, this energy loss can get reduced by adding capacitor banks at power substations to improve the power factor.

Transmission losses can happen due to several reasons such as radiation losses, conductor losses, heating losses (dielectric), coronal losses and coupling losses. Conductor losses mainly occur due to the current flow in the conductor. Since the transmission line contains more considerable resistance, this type of loss is unavoidable. This type of losses is also known as heating losses because it also generates heat energy.

There are several alternative methods are applied to reduce this type of losses such as by using a larger diameter of conductor and several other ways. There are different kind of losses which are applicable for the transmission line losses, and those are

- Coupling losses

- Corona losses

- Skin Effect

- Radiation Losses

- Dielectric Heating Losses

To prevent these kind of injuries, different methods are applied in the electrical industry. Transmission losses can be theoretically reduced by shortening the length of the transmission line. However, this is not a practical way of doing it because in some cases, the length of the transmission line needs to be a certain length. Another way to reduce the transmission losses are increasing the diameter of the wire, but when you are increasing the wire length, the cost of the conductors able to support more load also rises.